Boring Contractors Press

Tunnel Installations Public Relations | News Press Tunnel Installations Q&A

Tunnel Installations Public Relations | News Press Tunnel Installations Q&A

The following are answers to some common questions we receive about our directional boring project process -

Question & Answers

Use this list of questions and answers to evaluate the needs and requirements of your horizontal directional drilling (HDD) project.

How do I know Tunnel Installations is qualified to do the job?

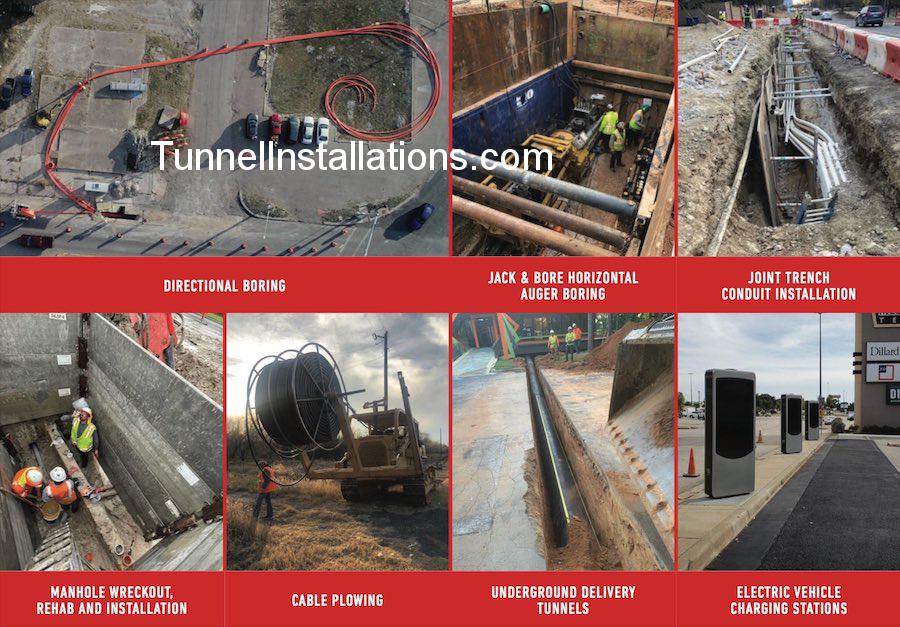

Tunnel Installations has drilled thousands of underground horizontal holes throughout the continental US. We are committed to meeting and exceeding the highest horizontal directional drilling safety standards.

What type and size utility pipe will I need?

We can install pipes made of HDPE, PVC and Steel ranging in diameter from 1 to 78 inches. The size of pipe you require depends on whether you are installing electric, gas, telecom, cable, fiber optic, water or sewer lines. The size of pipe also determines the machine that we will use on your job.

How much access space will I need for the HDD entry and exit pits?

The directional drilling entry pit is the starting point for the bore, and the exit point is the end of the bore. For an entry pit, a space generally between 3 and 40 feet is required, depending on the bend radius and directional bore path. At both the entry and exit pits, there will be some disruption to the surface and the emergence of drilling mud and underground spoils. How much space is needed to accommodate the bore pits is determined on project-by-project basis.

What size horizontal directional drilling machine will I need for the job?

We determine which of our HDD machines is best suited for the job by assessing the soil conditions, pipe size, and space available for drilling.

Do I need to have the location inspected for existing utilities?

Yes. Every project must have existing utilities located before we start drilling.

What kind infrastructure or water bodies will I be boring under?

We have directionally bored under rivers, highways, hospitals, airport and military runways. Our only requirement is that we can track the directional or auger drill head. When boring under water bodies and areas to dangerous or difficult to navigate by foot, we use boats or wire line technology to locate the drill head. Safety is our top concern, and we assess what controls we need for safety before setting up on any job site.

What time of year will I be boring?

We can bore in most weather conditions, including snow. Freezing temperatures may prohibit our equipment from drilling.

What kind of on site drilling mud disposal will I need?

During the drilling process, we use bentonite drilling mud. It is a naturally occurring substance produced via volcanic ash. On small jobs, we can remove the mud used during drilling. For larger jobs where the quantities of mud and spoils are large, we suggest taking on-site disposal into consideration.

How do I evaluate a quote for directional drilling versus a bid for open cutting surfaces?

The cost of surface restoration is the most overlooked aspect of an open cut excavation bid. The cost of fixing roads and controlling traffic are often not included in a bid for open cut excavation. When assessing an excavation bid, be sure to factor in the cost of repairing road damage and hiring traffic control. Traffic control and road restoration are often not major expenses when horizontal directional drilling is used. On our directional and auger boring quotes, we inform you of all costs to complete the directional drilling project.

Why should I choose horizontal directional drilling over open cut excavation?

Horizontal directional drilling equipment requires a relatively short set-up time; a small machine can be set up and start boring within an hour. Labor requirements are minimal, as it only takes a small crew to operate a small drilling machine. The need for traditional excavation during horizontal directional drilling is minimal or non-existent.

In open surface areas, horizontal directional drilling (HDD) is an efficient way to cross rivers, highways, railroad tracks, even active airplane runways, without major disruptions to traffic or costs for traffic management. In crowded and dense urban areas, directional boring is increasingly viewed as the more desirable technological choice because:

Existing surface disruption is minimized

Surface restoration costs (roads, infrastructure) are minimized

There is less impact on owners property

Minimizes the need for earth removal and the long-term costs of open-cut trench settlement

Tunnel Installations is a recognized leader in the boring industry. We provide directional and auger boring services to install underground electric, phone, cable, fiber optics, water, sewer, gas and irrigation utility lines for both large and small projects.

Tunnel Installations Public Relations | News Press TunnelInstallations.com

Tunnel Installations Public Relations | News Press TunnelInstallations.com

To learn more about Tunnel Installations and our latest news, use our Contact Us form to request a Press Kit

Tunnel Installations Public Relations | News Press Contact Phone Number and Contact Form

Tunnel Installations Public Relations | News Press Contact Phone Number and Contact Form

To get more news about Tunnel Installations call 866.846.9264 to request a Press Kit